In today’s high-demand fabrication environment, precision and speed are essential. That’s where the DORJE Series from Advanced Power Sources Ltd. (APS) delivers—offering high-speed, high-accuracy metal cutting across a variety of materials.

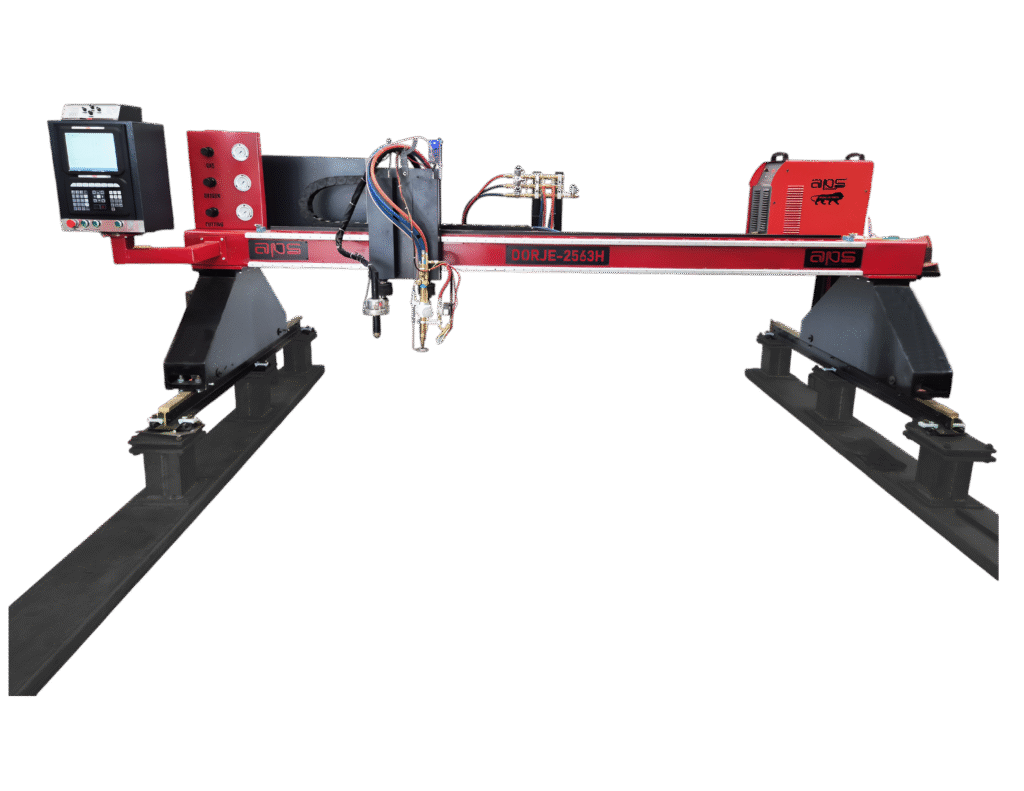

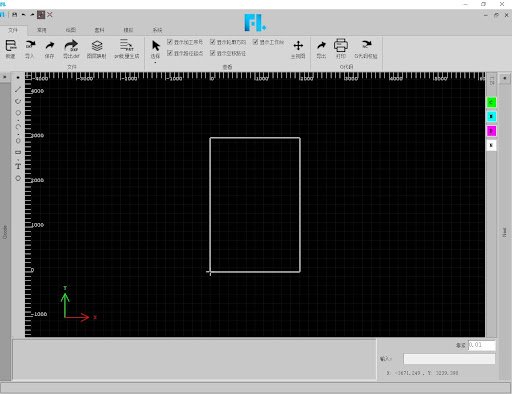

The system is built around a robust gantry frame and a computer-guided plasma torch, enabling flawless, repeatable cuts with minimal operator intervention. Operated through pre-programmed instructions, the CNC Cutting Machine ensures consistent, reliable performance in even the most demanding heavy-duty fabrication settings.

Whether you’re working with mild steel, stainless steel, or aluminum, this advanced cutting solution offers long-lasting durability and exceptional efficiency—ideal for workshops, manufacturing plants, and automation-focused industries. To explore the technology behind this innovation, visit the Wikipedia article on Numerical Control.

Experience next-level cutting precision with the CNC Cutting Machine that meets the evolving needs of modern metalworking.

| Model No. | Dimensions (mm) | Rail Length (mm) | Cutting Area (mm) | ||||

|---|---|---|---|---|---|---|---|

| A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | |||

| DORJE-1530H | 1250 | 1150 | 2350 | 3100 | 50 | 4000 | 1500 x 3000 |

| DORJE-1563H | 1250 | 1150 | 2350 | 3100 | 50 | 8000 | 1500 x 6300 |

| DORJE-2063H | 1250 | 1150 | 2850 | 3600 | 50 | 8000 | 2000 x 6300 |

| DORJE-2563H | 1350 | 1400 | 3550 | 4520 | 100 | 8000 | 2500 x 6300 |

| DORJE-25120H | 1350 | 1400 | 3550 | 4520 | 100 | 14000 | 2500 x 12000 |

| DORJE-3063H | 1350 | 1400 | 4050 | 4820 | 100 | 8000 | 3000 x 6300 |

| DORJE-30120H | 1350 | 1400 | 4050 | 4820 | 100 | 14000 | 3000 x 12000 |

| Specification | Details |

|---|---|

| Maximum Freewheeling Velocity | 12,000 mm/min |

| Flame Cutting Velocity Range | 50 to 700 mm/min |

| Flame Cutting Thickness Range | 5 mm to 200 mm |

| Position Accuracy | ±0.5 mm/meter |

| Repeatability | ±0.5 mm/meter |

| Shape Accuracy | ±0.5 mm/meter |

| Kerf Compensation | Up to 15 mm (in 0.1 mm increments) |

| Torch Height Adjustment Range | <150 mm (Flame/Plasma) |

| Specification | Details |

|---|---|

| Torch Type and Quantity | – Oxyfuel Torch: 1 No. (PNME type, Material: Mild Steel) – Plasma Torch: 1 No. (Material: MS / SS, depends on power source and torch selection) – Torch quantity customizable as per requirement |

| Cutting Thickness Range | – Oxyfuel Cutting: 5 mm to 200 mm (Piercing up to 80 mm) – Plasma Cutting: 1 mm to 35 mm (as per plasma power source capacity) |

| Drive Mode | – Servo Motor Based System – Dual Drive on Y-Axis – Single Drive on X-Axis |

APS welding is always ready to help you.

For Sales Enquiries:

Contact: +91 9601 444 111

For booking service call:

Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.