The Plasma Torch AP80FT is a high-performance cutting tool engineered for precision and durability in industrial metalworking applications. Designed for compatibility with a range of CNC plasma cutting systems, the AP80 delivers consistent arc stability, making it ideal for cutting steel, stainless steel, and aluminum. Its advanced design supports long consumable life and high-quality cuts, even in demanding environments. Whether in fabrication shops or heavy-duty operations, the Plasma Torch AP80 ensures efficient performance and reduced downtime. Learn more about the science behind plasma cutting on Wikipedia.

We offer widest range of consumable option for a variety of welding application needs.

Quality is the core of our products. We use the best raw materials and manufacturing process to achieve perfect quality.

We make our products in-house and thus provide our customers with a value for money product.

We offer Bulk discount for OEM companies and Dealers - Distributors.

Type: Air-cooled plasma cutting torch

Model: AP80FT (Flat Type)

Usage: Designed for use with plasma cutting machines up to 100A

Cutting Thickness: Capable of clean cuts up to 20–25 mm depending on the power source

Technology: Non-HF (High-Frequency) pilot arc start, safe for CNC use

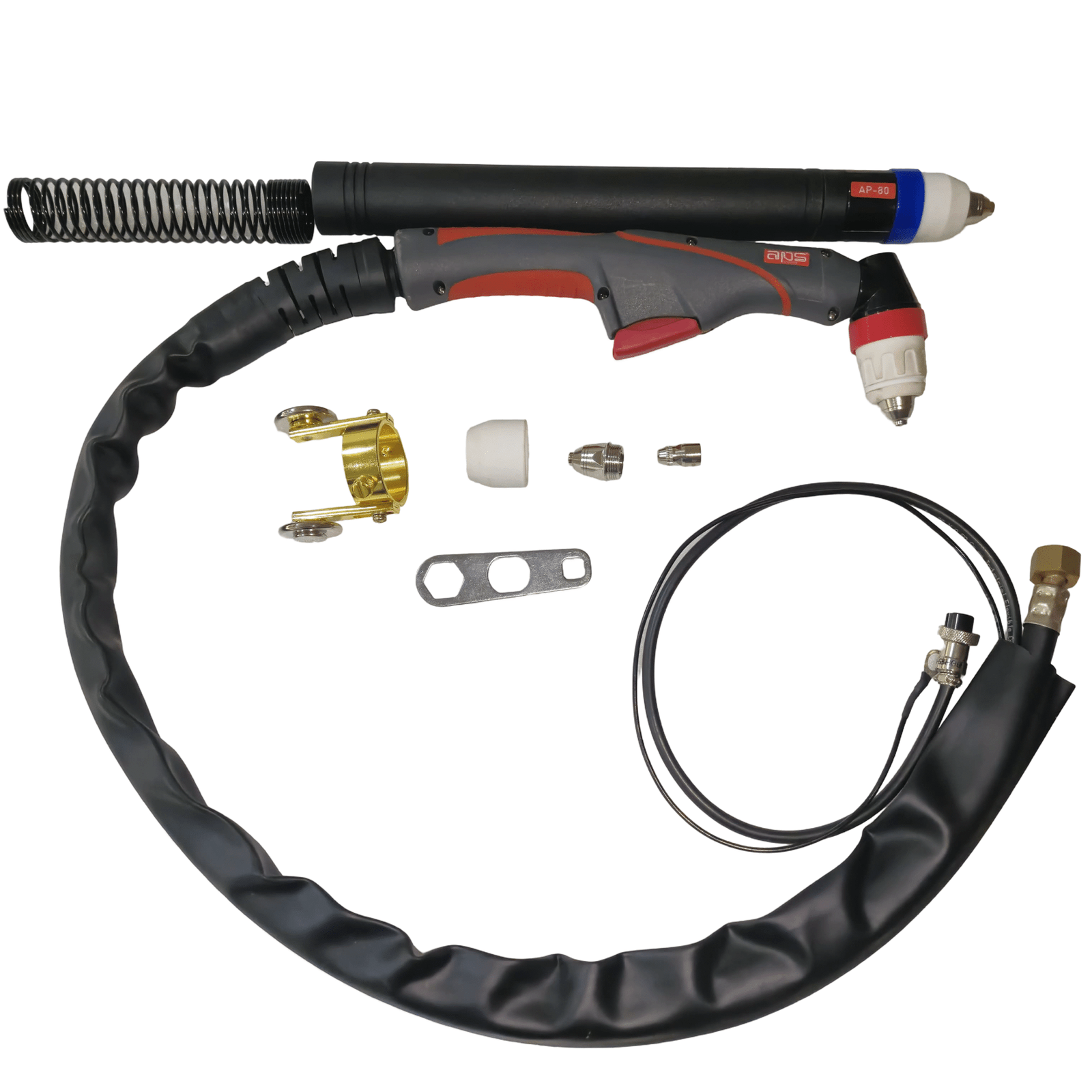

The AP80FT torch includes:

Torch Head (flat design for easy access to cutting zones)

Electrode

Nozzle

Swirl Ring

Shield Cap

Handle and Trigger Assembly

Cable Assembly

Each part is replaceable and commonly available in the APS.

The Plasma Torch AP80FT is a high-performance, air-cooled cutting torch engineered for precision and power. Designed for industrial use, the Plasma Torch AP80FT efficiently cuts through steel, aluminum, and stainless steel up to 25mm thick. Featuring a 6-meter cable and Euro connector, it offers excellent flexibility and ease of use. With an 80A current rating, the Plasma Torch AP80FT is ideal for professionals seeking clean, reliable cuts. Built with advanced air-cooled technology, this torch ensures durability and consistent performance. Learn more about plasma cutting and enhance your workflow with the Plasma Torch AP80FT today.

High-quality consumables like nozzles, and electrodes ensure consistent performance and clean welds or cuts. Made from durable materials, they offer longer service life, reduce downtime, and improve efficiency. Using precision consumables leads to superior results and cost-effectiveness in welding and cutting applications.

The electrode for the PLASMA Torch AP80FT is designed for high-performance plasma cutting. Made from premium materials, it ensures consistent arc stability, efficient heat transfer, and long-lasting durability. Ideal for cutting steel, aluminum, and stainless steel, the electrode provides precise cuts with minimal spatter and extended torch life.

The copper nozzle for plasma cutting is designed to optimize gas flow and heat dissipation, ensuring precise and clean cuts. It helps maintain a stable arc, reduces spatter, and provides better control over the cutting process. Copper’s excellent thermal conductivity and durability make it perfect for high-temperature environments, improving the overall efficiency and life span of the cutting torch.

Designed for precise and clean cuts, suitable for cutting a variety of metals including steel, aluminum, and stainless steel.

Features a cooling system to prevent overheating, ensuring consistent performance and torch longevity.

Designed with high-quality materials for heavy-duty use, ensuring longevity and reliability in demanding cutting tasks.

Works with a wide range of consumables, offering flexibility for different cutting needs.

APS Welding presents the AP80 Plasma Cutting Torch 80, designed for industrial applications requiring precision, speed, and durability. Trusted by metal fabrication industries across India, this torch offers high performance, low maintenance, and CNC compatibility at the best price.

Whether you are cutting stainless steel, mild steel, or aluminum, the AP80 Plasma Torch ensures a clean, precise cut every time.

The AP80 Plasma Cutting Torch 80 is an advanced cutting solution for industrial and commercial applications. Designed for both manual and CNC plasma cutting machines, this torch offers:

High-speed cutting with superior accuracy

Long-lasting consumables for reduced maintenance

Energy-efficient operation suitable for heavy-duty tasks

Compatibility with a wide range of metal types

Engineered for durability and consistent performance, the AP80 torch is ideal for workshops, fabrication units, and manufacturing industries.

Heavy Duty Construction: Built to withstand rigorous industrial use.

High Cutting Speed: Cuts metals efficiently, reducing operational time.

CNC Compatible: Easily integrates with CNC plasma cutting machines.

Low Maintenance: Durable torch tips and electrodes minimize replacement frequency.

Energy Efficient: Uses less power without compromising on cutting performance.

Metal Compatibility: Works on stainless steel, mild steel, aluminum, and more.

This combination of features ensures maximum uptime, precision, and cost-effectiveness for your operations.

The AP80 Plasma Cutting Torch 80 is ideal for a variety of industrial and commercial applications:

Metal Fabrication Workshops: Perfect for sheet metal, stainless steel, and aluminum cutting.

Automotive Manufacturing: Efficient for chassis, body parts, and component cutting.

Heavy Engineering: Handles thick metal plates and industrial projects with ease.

Construction & Infrastructure: Ideal for structural steel cutting and metal frameworks.

CNC Plasma Cutting Units: Works seamlessly with automated cutting systems for consistent results.

This torch is versatile enough to serve both manual operators and automated CNC setups, making it a preferred choice in industrial environments.

APS Welding is a trusted manufacturer and supplier of plasma cutting equipment in India. Reasons to choose APS Welding include:

ISO certified industrial products

Superior build quality and reliability

Energy-efficient and low maintenance designs

Dedicated customer support and technical guidance

Competitive pricing and fast delivery

With APS Welding, you get industrial-grade plasma cutting solutions that guarantee performance and durability.

APS Welding machines are manufactured in compliance with recognized international and national standards to ensure reliability and safety:

These certifications ensure high reliability, operational safety, and consistent performance

for heavy industrial welding applications

The AP80 torch can cut mild steel, stainless steel, aluminum, and other conductive metals up to 30 mm thickness.

The high-quality electrodes and nozzles are designed for long life, reducing replacement frequency and operational costs.

Yes, it is fully compatible with CNC plasma cutting machines as well as manual setups.

APS Welding offers competitive pricing. Contact us for an exact quote and bulk order discounts.

Absolutely. AP80 is designed for heavy-duty cutting with precision and durability.

Looking for complete welding solutions? Explore our advanced welding machines and accessories:

APS welding is always ready to help you. For Sales Enquiries:Contact: +91 9601 444 111For booking service call:Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.