Introduction to Wire Feeding in Modern Welding

Wire feeding is an essential part of modern welding techniques, which enable accurate and continuous addition of filler material to the weld pool. Modern wire feeding techniques have greatly enhanced the quality, efficiency, and energy savings in various sectors like aerospace, automobile, shipbuilding, and heavy machinery.

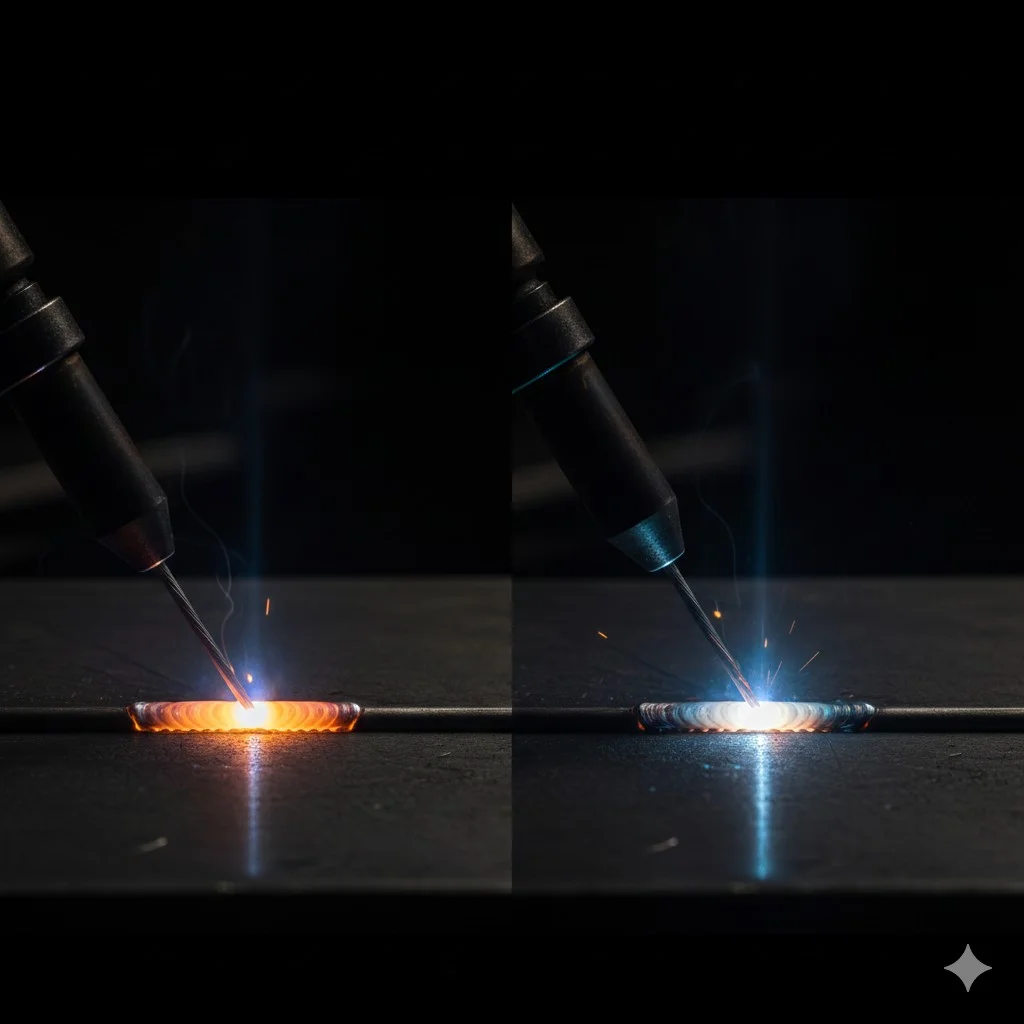

Among various techniques, cold wire feeding and hot wire feeding are common practices. Understanding the difference between cold wire feeding and hot wire feeding will enable welding engineers and fabricators to choose the appropriate technique for strength, efficiency, and economy.

What Is Cold Wire feeding?

Cold wire feeding is a welding technique where the filler wire is fed mechanically into the weld pool without any electrical preheating of the wire.

Working Principle of Cold Wire feeding

In cold wire feeding:

- The filler wire is introduced into the molten weld pool

- The wire melts solely due to heat from the welding arc or laser

- No current flows through the filler wire itself

This method is commonly used in TIG (GTAW), laser welding, and plasma welding applications where precision is critical.

Equipment Used in Cold Wire feeding

- Mechanical wire feeder

- Wire guide tubes or nozzles

- Main welding power source

- Process control unit

According to AWS Welding Handbook, cold wire feeding provides excellent control over filler addition, making it ideal for thin materials and high-quality welds.

What Is Hot Wire feeding?

Hot wire feeding is an advanced technique in which the filler wire is electrically preheated before entering the weld pool.

Working Principle of Hot Wire feeding

In hot wire feeding:

- Electrical current passes through the filler wire

- Resistance heating raises the wire temperature

- The wire reaches near-melting temperature before entering the weld pool

Because the wire is already hot, the welding arc requires less energy to melt it, improving overall efficiency.

Equipment Used in Hot Wire feeding

- Hot wire power source

- Electrically insulated wire feeder

- Control system for wire current and feed speed

- Integrated welding torch

Manufacturers such as Fronius and ESAB describe hot wire feeding as a productivity-enhancing process for high-deposition welding.

Key Difference Between Cold and Hot Wire feeding

Heat Input and Energy Efficiency

Cold wire feeding relies entirely on arc heat, resulting in higher heat input to the base metal. Hot wire feeding reduces arc energy requirements, improving energy efficiency and lowering distortion.

Deposition Rate and Productivity

Hot wire feeding achieves significantly higher deposition rates compared to cold wire feeding, making it suitable for thick-section welding and large-scale fabrication.

Weld Quality and Control

Cold wire feeding offers superior control of the weld pool, especially for thin materials and precision components. Hot wire feeding delivers excellent weld quality when properly controlled but focuses more on productivity.

Advantages of Cold Wire feeding

- Excellent weld pool control

- Lower equipment and setup cost

- Ideal for thin materials and precision welding

- Reduced risk of overheating small components

Cold wire feeding is often preferred in aerospace and high-precision manufacturing.

Advantages of Hot Wire feeding

- Higher deposition rates

- Lower overall heat input to base material

- Increased welding speed and productivity

- Improved efficiency for thick materials

According to Lincoln Electric, hot wire feeding can increase deposition rates by up to 50% compared to cold wire methods.

Limitations of Cold and Hot Wire feeding

Cold Wire feeding Limitations

- Lower deposition rates

- Less efficient for thick sections

- Longer welding time

Hot Wire feeding Limitations

- Higher equipment cost

- More complex setup

Requires precise control systems

Industrial Applications

Aerospace and Precision Welding

Cold wire feeding is widely used due to its excellent control and minimal heat input.

Heavy Fabrication and Shipbuilding

Hot wire feeding is preferred for welding thick plates and large structures where productivity is critical.

Safety and Process Control Considerations

- Proper electrical insulation is essential in hot wire feeding

- Wire feed speed must be carefully controlled in both methods

- Operators should follow AWS safety standards

- Regular equipment inspection ensures consistent performance

Frequently Asked Questions (FAQs)

1. What is the main difference between cold and hot wire feeding?

The main difference is that hot wire feeding electrically preheats the wire, while cold wire feeding does not.

2. Which method gives better weld quality?

Cold wire feeding offers better control for precision welding, while hot wire feeding focuses on productivity.

3. Is hot wire feeding more efficient?

Yes, it improves deposition rates and energy efficiency.

4. Can hot wire feeding be used with TIG welding?

Yes, hot wire TIG welding is commonly used for thick materials.

5. Is cold wire feeding suitable for automation?

Yes, it is widely used in robotic and laser welding systems.

6. Which industries use hot wire feeding the most? Shipbuilding, heavy fabrication, and pressure vessel manufacturing

Conclusion

Understanding the difference between cold and hot wire feeding is essential for selecting the right welding process. Cold wire feeding excels in precision, control, and thin materials, while hot wire feeding offers higher deposition rates, efficiency, and productivity for heavy-duty applications. By choosing the correct method based on application requirements, manufacturers can achieve stronger welds, lower costs, and improved performance.

For official standards and best practices, consult the American Welding Society (AWS):

🔗 https://www.aws.org