In the world of metal fabrication, precision and efficiency are everything. One tool that has become indispensable for welders and manufacturers alike is the welding positioners. Designed to rotate, tilt, and securely hold workpieces during welding, a welding positioner ensures that every joint is welded with accuracy, consistency, and safety.

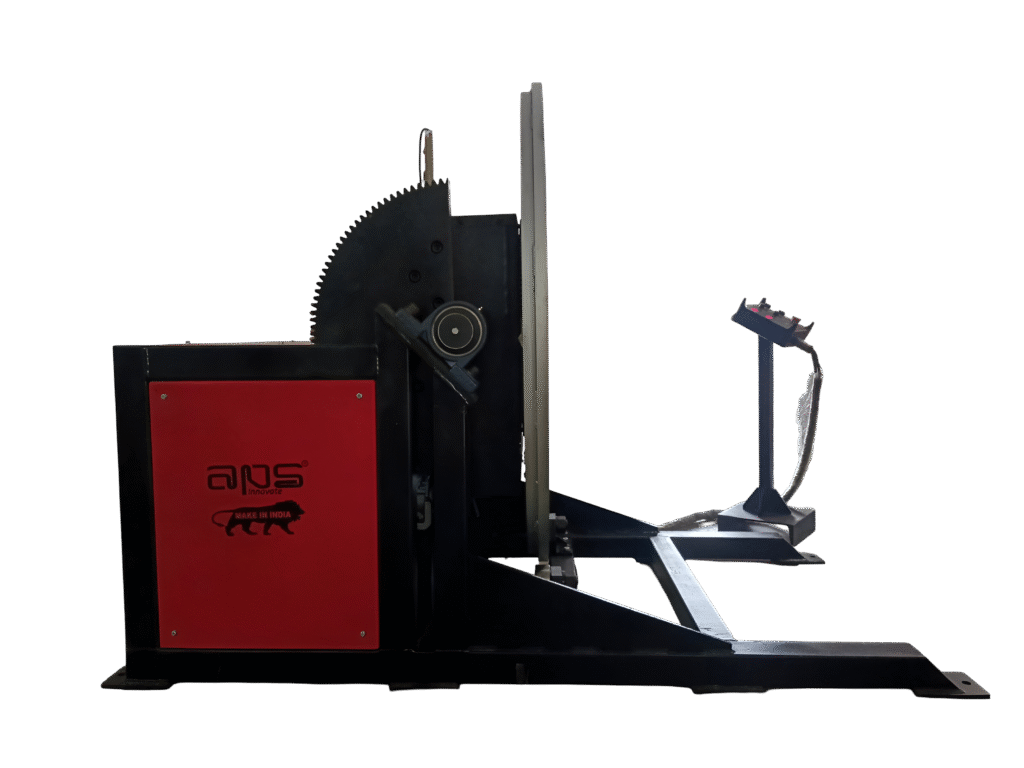

Among the most reliable solutions in this category is the Welding Turn Table, a robust and versatile welding positioner engineered for heavy-duty applications.

What is a Welding Positioner?

A welding positioners is a mechanical device that holds and rotates a workpiece, allowing welders to achieve the best welding angle without manual repositioning. It eliminates awkward welding positions, reduces operator fatigue, and ensures uniform weld quality.

Whether you’re welding small components or heavy industrial parts, a welding positioner transforms the welding process into a faster, safer, and more precise operation.

| Model | ATT-50 | ATT-150 | ATT-300 | ATT-500 | ATT-1000 | ATT-2000 | ATT-5000 | ATT-10000 |

| Load Capacity at 0° (kg) | 50 | 150 | 300 | 500 | 1000 | 2000 | 5000 | 10000 |

| Load Capacity at 90° (kg) | 25 | 75 | 150 | 250 | 500 | 1000 | 2500 | 3000 |

| Table Diameter (mm) | 1200 | 1500 | 2000 | 2000 | 3000 | 4000 | 5000 | 5000 |

| Rotation Speed (RPM) | 0– 1.5 | 0– 1.5 | 0– 1.5 | 0– 1.5 | 0– 1.5 | 0– 1.5 | 0– 1.5 | 0– 1.5 |

| Drive Method | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD | AC motor with reduction gear and VFD |

| Face Plate (mm) | 305 | 450 | 650 | 800 | 1200 | 1200 | 1500 | 2000 |

| Tilting Method | Manual | Manual | Manual | Motorised | Motorised / Hydraulic | Motorised / Hydraulic | Motorised / Hydraulic | Motorised / Hydraulic |

| Tilting Angle | 0°– 90° | 0°– 90° | 0°– 120° | 0°– 120° | 0°– 120° | 0°– 120° | 0°– 120° | 0°– 120° |

| Tilting Speed (RPM) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Center of Gravity (mm) | 100 | 100 | 150 | 150 | 150 | 150 | 190 | 200 |

Investing in a welding positioner like the Welding Turn Table delivers multiple advantages:

Welding positioners are widely used in industries where precision and strength are critical. The Welding Turn Table is perfect for:

When choosing a welding positioner, reliability, load capacity, and ease of use matter most. The Welding Turn Table offers all of these, combining heavy-duty performance with precise control. With its robust design and advanced features, it helps manufacturers achieve higher productivity and better welding results.

High torque gearbox for smooth rotation

Precision machined rotary table

Variable frequency drive (VFD) control

Strong fabricated steel structure

Foot pedal or remote control operation

Safety locking & overload protection

ISO 9001:2015 Certified Manufacturer

Made in India – Robust & Durable Design

High Load Capacity & Smooth Rotation

Accurate Tilting & Positioning for Perfect Welds

Suitable for MIG, TIG, SAW & SMAW Welding

Pan-India Supply & After-Sales Support

Our welding positioners help rotate and tilt the workpiece into the most ergonomic welding position, ensuring consistent weld penetration and reduced welder fatigue.

Ideal for circular welding jobs, rotary welding positioners provide smooth 360° rotation with variable speed control for precise welding operations.

Designed for flexibility, tilting welding positioners allow the workpiece to tilt at various angles, making complex welding tasks easier and more accurate.

Built for high-load applications, our heavy-duty welding positioners are suitable for large components, pressure vessels, pipes, and structural fabrication.

We offer custom-built welding positioners based on load capacity, table size, rotation speed, and automation requirements.

Pipe welding & fabrication

Pressure vessels & storage tanks

Structural steel fabrication

Automotive & heavy engineering

Shipbuilding & infrastructure projects

Improves weld quality & consistency

Increases productivity & efficiency

Reduces rework and welding defects

Enhances operator safety

Saves time & labor cost

APS Welding machines are manufactured in compliance with recognized international and national standards to ensure reliability and safety:

These certifications ensure high reliability, operational safety, and consistent performance

for heavy industrial welding applications

With years of experience in welding automation, APS Welding Automation delivers reliable, efficient, and cost-effective welding positioners trusted by industries across India. Our solutions comply with international quality standards and are backed by expert technical support.

A welding positioner is used to rotate and tilt workpieces into the ideal welding position for better weld quality and productivity.

Yes, APS Welding Automation is an ISO 9001:2015 certified manufacturer.

Yes, we design and manufacture customized welding positioners as per customer requirements.

Yes, it is designed for heavy-duty industrial applications with strong thermal protection and stable duty cycle.

Our welding positioners are available in multiple load capacities, including heavy-duty industrial models.

APS welding is always ready to help you. For Sales Enquiries:Contact: +91 9601 444 111For booking service call:Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.