Weld Visor is a browser based welding software.

It can be operated from your PC/laptop/mobile connected to internet.

You can create, store and analyse your project data/standard welding procedures/real time welding data/welding equipment data/welder data

If You Face This Problems

Solution for all the problems is simple and single.

Weld Visor is your smart welding supervisor which helps your solve many practical issues you may be facing

➔Welding assistant device should be connected to your welding equipment.

➔This device can be integrated and connected to welding equipment of any brand.

➔It helps user view welding parameter data at which he is supposed to weld.

➔It helps us capture the live welding data.

➔It also helps us in live control of welding parameter values at which welder is welding

➔All the data can be exported to excel, filtered date/project/welder wise.

You can create, edit, copy projects and save all necessary data for the same such start date, estimated end date, project raw materials etc.

Know all your pending projects at one glance, filter all the data available based on start date, end date/project no/status.

Standard welding procedure/s can be assigned to the projects.

This feature helps you to escape from the tedious job of all the manual paper work of welding procedure data capture.

You can create all your welding procedures according to various standards and assign the same to multiple projects.

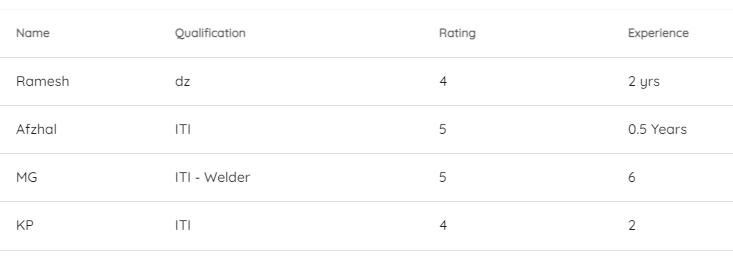

You can create welders and save all necessary data such qualification, salary etc.

System automatically captures welder data such as hours of work, accuracy of welding etc.

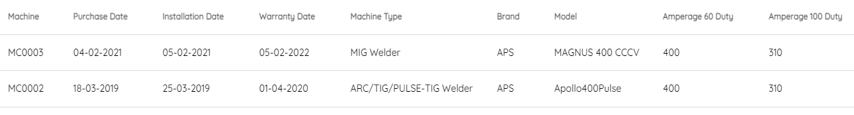

You can create welding equipment data, save all necessary data such purchase date, Warranty completion date, installation date etc.

These equipments can be integrated with welding assistant device to automatically capture live running data and also control the equipment.

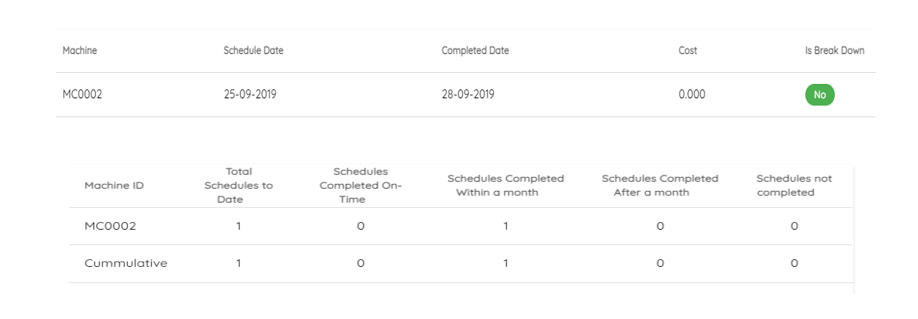

➔You can create and update your equipment maintenance schedules.

➔Track if machine maintenance are done on-time to avoid complete break-downs.

| Item | Material | Weight (Kgs) | Unit Price/kg | Price |

|---|---|---|---|---|

| Two hemispherical heads | SA537 | 13,927 | ₹ 180 | ₹ 25,06,876 |

| Shell (low-alloy steel) | SA724 | 32,296 | ₹ 100 | ₹ 32,29,575 |

| Shell liner (stainless steel) | Roll-bonded 304L on SA516 | 3,571 | ₹ 185 | ₹ 6,60,575 |

| Base support subassembly: | – | – | – | – |

| Skirt | SA516 | 3,073 | ₹ 53 | ₹ 1,62,850 |

| Base top ring and gussets | SA516 | 1,254 | ₹ 53 | ₹ 66,448 |

| Two nozzles (H₂ in and out) | SA336 | 261 | ₹ 250 | ₹ 65,317 |

| – | – | – | – | ₹ 66,91,640 |

| Item | Labor Hours |

|---|---|

| Assembling and welding of stainless-steel shell liner | 223 |

| Assembling and welding of low-alloy steel layers | 610 |

| Welding of skirt | 135 |

| – | 968 |

| Item | Cost | Approx. Cost Savings | Minimum | Maximum |

|---|---|---|---|---|

| Bill of materials | ₹ 66,91,640 | 1–3% Material Reduction due to lesser rework/scrap | ₹ 66,916.40 | ₹ 2,00,749.21 |

| Labor (labor rate of ₹85/hr) | ₹ 82,280 | 2–10% Labour Cost reduction due to lesser rework/inefficiency | ₹ 1,645.60 | ₹ 8,228.00 |

| Welding consumables (e.g., rod and gas) | ₹ 3,68,000 | 0.5–1% Welding consumables reduction | ₹ 1,840.00 | ₹ 3,680.00 |

| – | – | Misc. Saving (Manual WPS printing, monitoring system) | ₹ 5,000.00 | ₹ 15,000.00 |

| Total | ₹ 71,41,920 | ₹ 75,402.00 | ₹ 2,14,257.61 |

APS welding is always ready to help you. For Sales Enquiries:Contact: +91 9601 444 111For booking service call:Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.