| Model | Column Size (m) | Vertical Stroke (mm) | Horizontal Stroke (mm) | Elevation Speed (m/min) | Traverse Speed (m/min) | Max Load (kg) | Rotation | Safety |

|---|---|---|---|---|---|---|---|---|

| MINI CNB | 1 × 1 | 1000 | 1000 | 0.15–1.5 | 0.15–1.5 | 30 | Fix/Manual Rotation | No |

| MINI CNB2 | 1.5 × 1.5 | 1500 | 1500 | 0.15–1.5 | 0.15–1.5 | 30 | Fix/Manual Rotation | No |

| MINI CNB3 | 2 × 2 | 2000 | 2000 | 0.15–1.5 | 0.15–1.5 | 30 | Fix/Manual Rotation | No |

| CNB | 2 × 2 | 2000 | 2000 | 0.15–1.5 | 0.15–1.5 | 80 | Fix/Manual Rotation | No |

| CNB4 | 3 × 3 | 3000 | 3000 | 0.15–1.5 | 0.15–1.5 | 80 | Manual / Motorized | Yes |

| CNB5 | 4 × 4 | 4000 | 4000 | 0.15–1.5 | 0.15–1.5 | 80 | Manual / Motorised | Yes |

| CNB6 | 5 × 5 | 5000 | 5000 | 0.15–1.5 | 0.15–1.5 | 80 | Manual / Motorised | Yes |

| EHD CNB | 3 × 3 | 3000 | 3000 | 0.15–1.5 | 0.15–1.5 | 200 | Manual / Motorised | Yes |

| EHD CNB7 | 4 × 4 | 4000 | 4000 | 0.15–1.5 | 0.15–1.5 | 200 | Manual / Motorised | Yes |

| EHD CNB8 | 5 × 5 | 5000 | 5000 | 0.15–1.5 | 0.15–1.5 | 200 | Manual / Motorised | Yes |

| EHD CNB9 | 6 × 6 | 6000 | 6000 | 0.15–1.5 | 0.15–1.5 | 200 | Manual / Motorised | Yes |

| EHD CNB10 | 7 × 7 | 7000 | 7000 | 0.15–1.5 | 0.15–1.5 | 200 | Manual / Motorised | Yes |

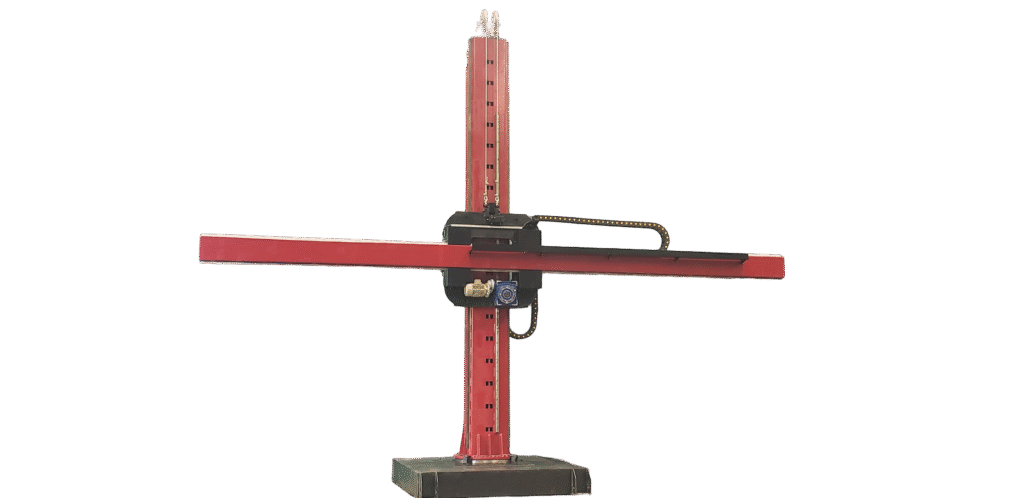

When handling large weldments, maintaining accuracy, speed, and consistency can be challenging with manual welding. This is where Column and Boom Welding Systems stand out. Designed to provide stability, reach, and flexibility, they have become an indispensable part of heavy fabrication industries.

A Column and Boom Welding Machine provides rigid column support and smooth boom movement, ensuring precise torch positioning. This results in uniform welds, fewer defects, and minimal rework.

With automated travel speeds and extended stroke lengths, Column and Boom Welding Systems can handle long weld joints continuously without operator fatigue. This drastically reduces welding time compared to manual welding methods.

Column and Boom Welding Machines are compatible with MIG (GMAW), TIG (GTAW), and SAW (Submerged Arc Welding) processes, making them versatile for different materials and thicknesses.

By automating the welding process, operators can control the Column and Boom Welding System from a safe distance using a remote pendant. This reduces exposure to heat, sparks, and fumes, creating a safer work environment.

From compact 1×1 models to large 7×7 EHD versions, Column and Boom Welding Equipment offers multiple sizes and load capacities. This flexibility makes them ideal for industries like shipbuilding, pressure vessels, wind towers, and pipeline fabrication.

Investing in Column and Boom Welding Automation delivers long-term cost savings. With higher productivity, reduced labor costs, and minimal rework, companies achieve a faster return on investment.

In modern fabrication, productivity and precision are no longer optional — they are essential. Welding automation has become the backbone of industries such as shipbuilding, structural fabrication, and pressure vessel manufacturing. Among the most effective automation tools is the Column and Boom Welding Machine, known for its ability to deliver consistent, high-quality welds.

APS Welding, a trusted name in welding equipment manufacturing in India, offers world-class Column and Boom Welding Systems. These machines are designed with durability, performance, and operator safety in mind, making them the preferred choice for industries that demand reliable welding automation solutions.

APS Welding’s Column and Boom Welding Systems are trusted across industries because of their reliability, precision, and versatility. These automation solutions are widely used in:

Shipbuilding & Offshore Structures – for welding large hulls, decks, and marine components

Pressure Vessels & Boilers – ensuring accurate and defect-free welds on thick materials

Heavy Structural Fabrication – for bridges, steel structures, and construction projects

Wind Towers & Renewable Energy – handling tall, cylindrical weldments with precision

Pipes & Tank Manufacturing – delivering consistent welds in pipe mills and storage tanks

APS welding is always ready to help you. For Sales Enquiries:Contact: +91 9601 444 111For booking service call:Contact: +91 9601 444 222

We design and manufacture all our products and thus we know the best about our products.

We are able to offer international technology and service at optimum prices.

Our team is regularly trained for updates in service techniques and also are constantly update on knowledge and skill.

We ensure you professionally managed sales and after sales support.

Office & Manufacturing Facility:

Survey No 172/1, Paikee 2, OLD GIDC Gundlav, Valsad, Valsad District, GUJARAT – 396035. INDIA.